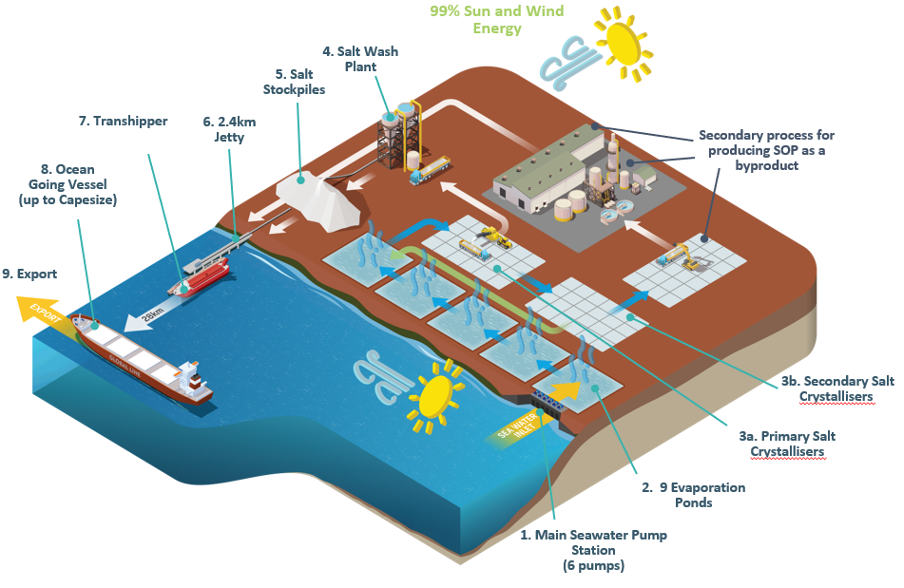

BCI Minerals’ salt-making process at the Mardie Salt and Potash Project will harness its unique location on the Pilbara coast to make the most of an abundant seawater resource and a production process driven mainly by natural solar and wind energy.

It’s a process that starts with filling the first ponds with seawater and progressively increasing salinity across evaporation ponds. While a simple and natural process, it’s a fine art to create the quality end-product.

The foundation of quality salt production

It begins with the Primary Seawater Intake Pumps, a series of powerful, highly advanced machines that pump around 180 gigalitres of seawater – or 70,000 olympic pools worth - each year from the ocean into a series of ponds.

This lays the groundwork for high-quality salt production and facilitates essential activities such as building the ecosystem and cultivating algae mats to seal pond floors.

The heart of salt production

Comprising about 90 per cent of the total salt field area, concentration ponds play a pivotal role in the salt production journey.

Over about 12 months, brine moves through these ponds, with sun and wind driving seawater evaporation, gradually increasing brine salinity.

As the brine becomes saltier, the rate of evaporation slows, necessitating more pond area to achieve the same water evaporation.

Guarding pond integrity

In the concentration ponds, algae extract nutrients from incoming seawater while seagrass acts as a natural filter, preventing silt from reaching salt crystallisers.

Algal mats within the ponds act as a seal, reducing water seepage, which means a higher volume of salt can be cultivated, and as the mats darken over time, they absorb solar radiation and enhance evaporation.

Maintenance of the algal mat's health is critical, requiring careful management of brine density to prevent disturbances and ensure the production of top-notch salt.

The culmination of quality control

Upon reaching pond nine, highly saturated brine is released into crystallisers, marking a crucial stage for quality control.

The focus is on crystallizing sodium chloride, although minor amounts of gypsum may also crystallize.

To ensure purity, the process teams meticulously manage density to control chemical properties and depth to regulate crystal size. Deep ponds foster fine crystals, while shallow ones yield coarse, hard crystals.

Following this, salt is washed and stockpiled.

From pond to port, and beyond

When the salt is ready for export, it will be conveyed along Mardie’s 2.4km purpose-built jetty and loaded onto the transhipper to fill ocean-going vessels.

BCI Minerals, will be the only salt manufacturer in Australia that can directly load capesize or extra-large vessels, thus giving it a freight advantage and direct access to key international markets.

Ensuring quality and sustainability

Once complete, Mardie is forecast to produce approximately 5.35 million tonnes of salt every year for 60 years, making it the largest salt project in Australia and the third-largest solar salt project in the world.

BCI Minerals meticulously orchestrates the entire salt production process, from filling ponds to crystallisation, ensuring a delicate balance that results in the production of high-quality salt.